Cylinder heads

We started by studying what we consider the most important factor for power/torque production on an engine and that will be cylinder head, the ports are ultimately responsible for the amount of air a cylinder is able to take in regardless of its displacement, by improving this area we normally always seen a great deal in gains

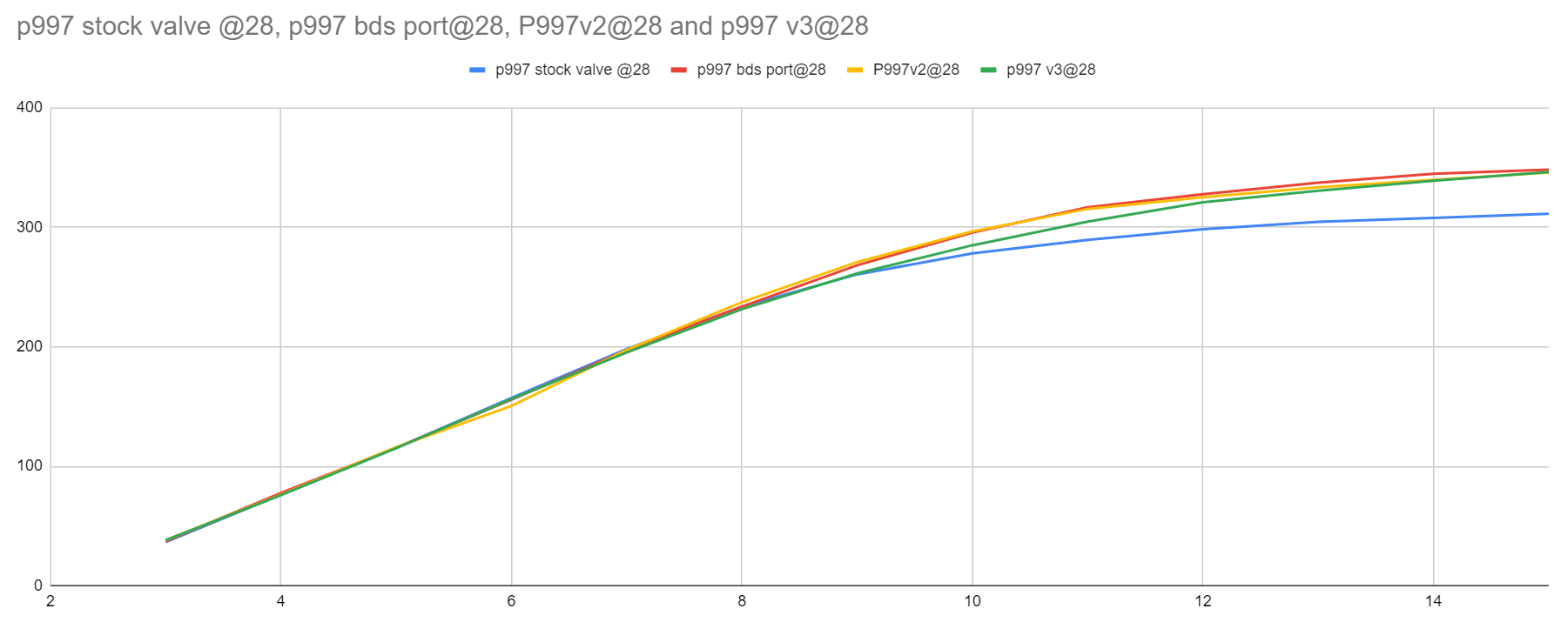

on cylinder head peak flow numbers are important but what makes it good is actually the avg value, you could have a head with a higher peak cfm but if the avg from 1mm-11mm(current lift used in these engines) was worse you would experience a worse performance, so we leave non of these behind and all tests get a report and compared, also some people think the bigger the better but often this isn’t the case. on these graphs bellow we done what we know works on the V1, V2 and V3 are internet tested, v2 filled in injector area and raised roof on port and v3 a larger throat area we can see what ones worked the best with this Port and valve combination

Results on V1 heads and carried work

We have now tested our cylinder heads and we seen an increase of torque and power all across the power curve, we found stock 3.8 intake manifold to become a big restriction at this point but we still seen a 5% power gain and combined with our plenum using a 82mm throttle body we saw a total of 8.5% gain also to mention peak power occurred a full 500rpm earlier exposing the intake manifold restrictions, on the torque in certain areas we had seen as much as 12% but a curve that holds way better. we currently developing further on the heads and also designing a full intake system.

When doing the head work we don’t cut corners as we know how important reliability is, during our porting process head goes through an extensive rebuild, we replace all the guides and valve seats as well along with the usual seals, on valve seats we found it was important to replace the original ones as there are reports of seats failing and we have found original seat size not to be ideal for valve size as we consider it on the small side, this along with changing the throat size and shape will only make a weak point even weaker and so we opted to make this a part of the job. valve seats are over sized offering better support on the head this way removing the possibility of failing. our seats are cnc multi angle cut.

BDS V4 head

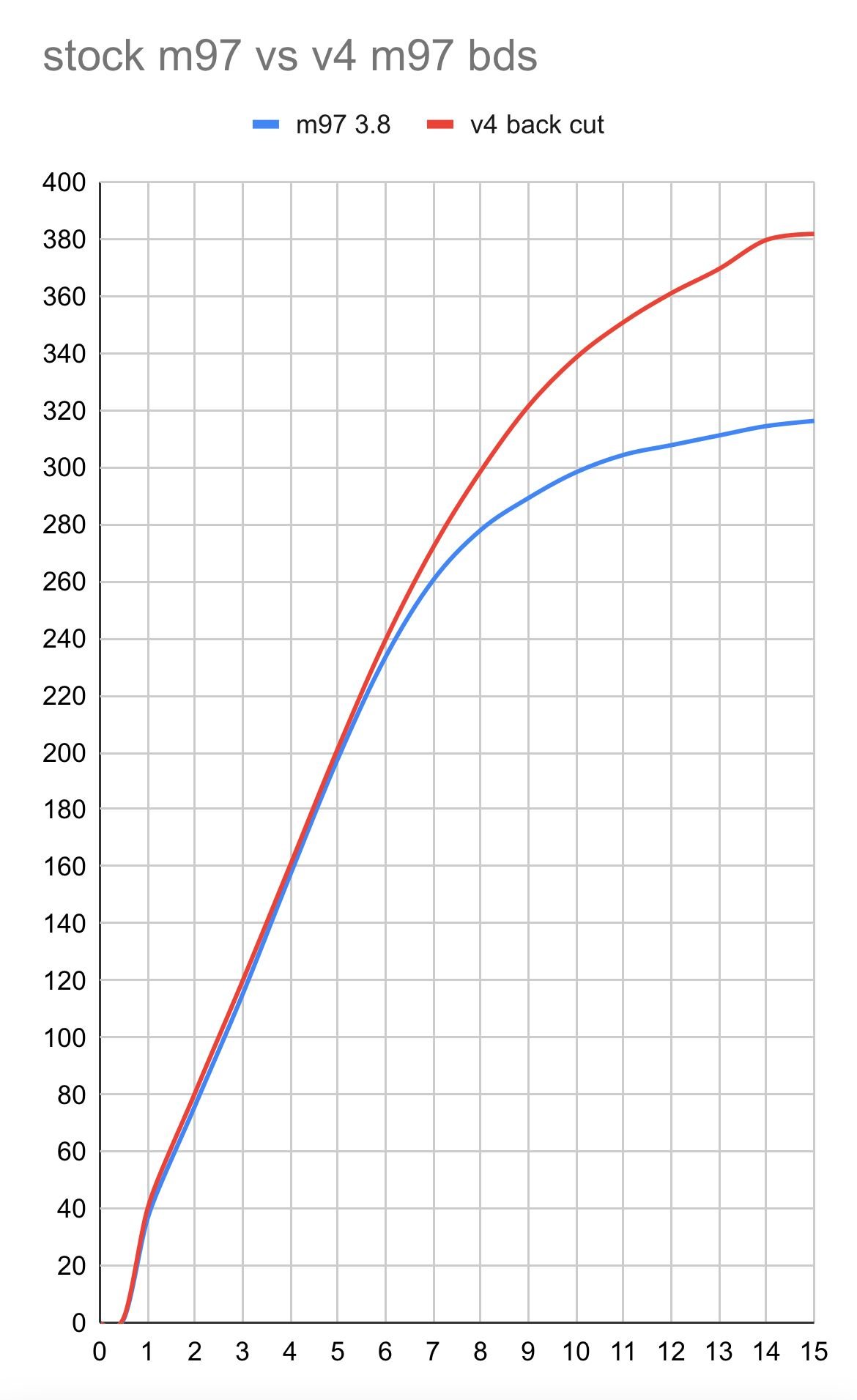

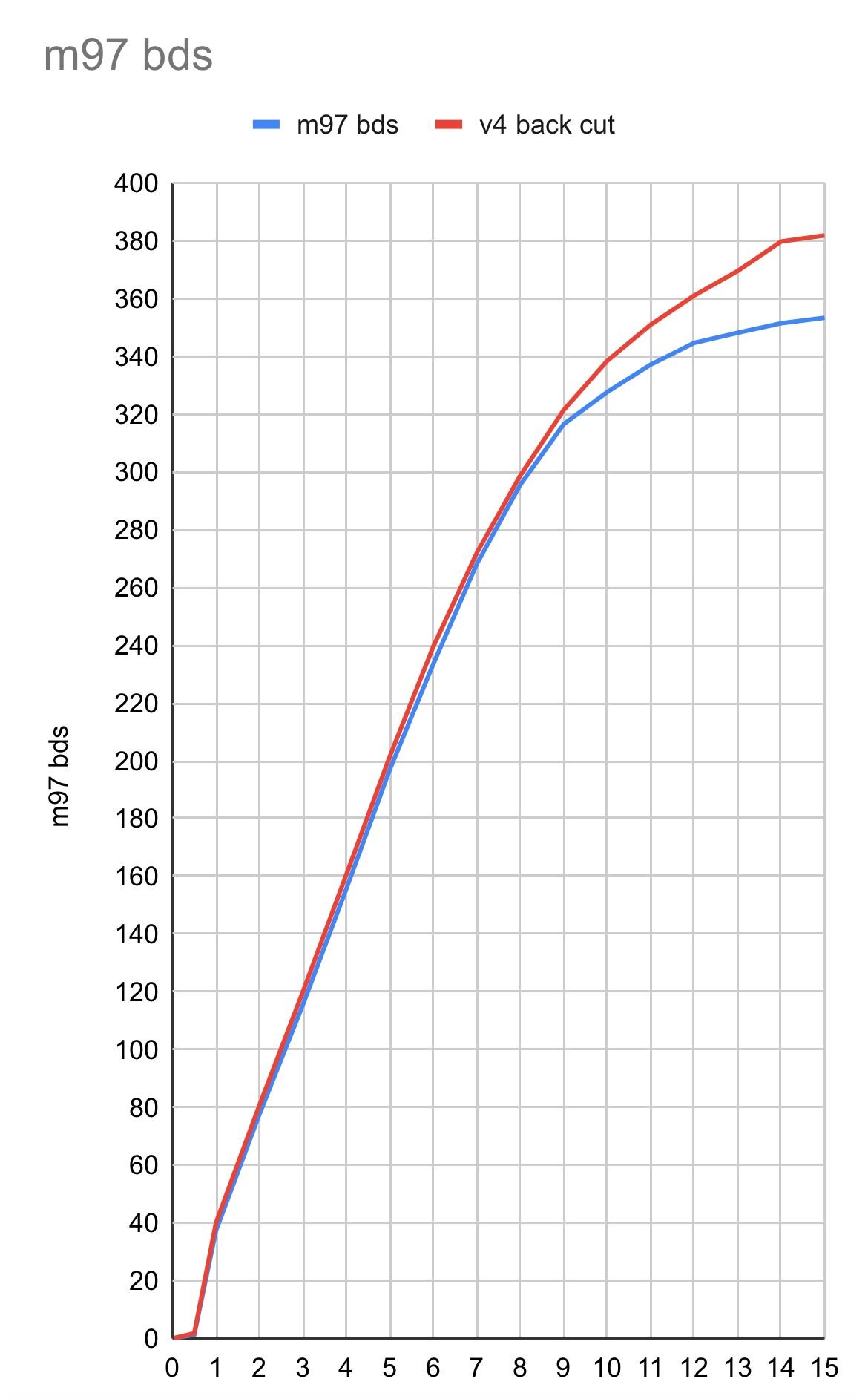

We have now finishing testing our best port till now, we managed an increase on CFM all across the lift area and achieved some very good gains, this head peaks at 380cfm@15mm lift (0.590”) these heads are designed for those seeking very high power outputs and rpm, we worked on port in order to have great port speed as well so nothing is compromised also best results will be achieved with a good camshaft choice something we are currently developing

bellow graphs comparing stock head cfm vs v4 and our current used v1 vs v4.