BMW M44 rocker geometry correction kit (high lift kit)

We've been hard at work developing engines for many years, and along the way we've encountered just about every problem you can imagine. But with each challenge, we've always found a way to overcome it. In fact, we've come up with solutions for issues that simply weren't available on the market.

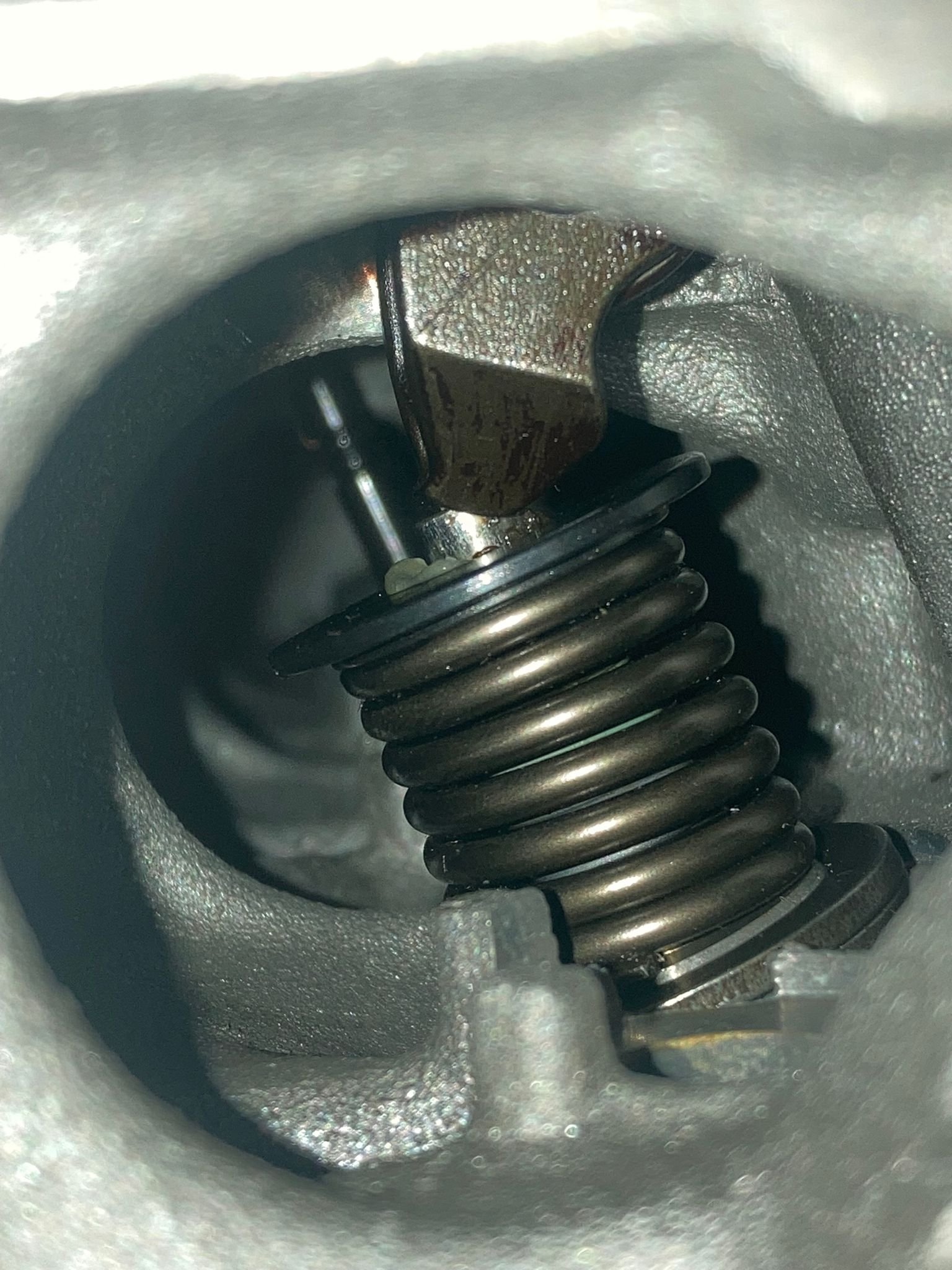

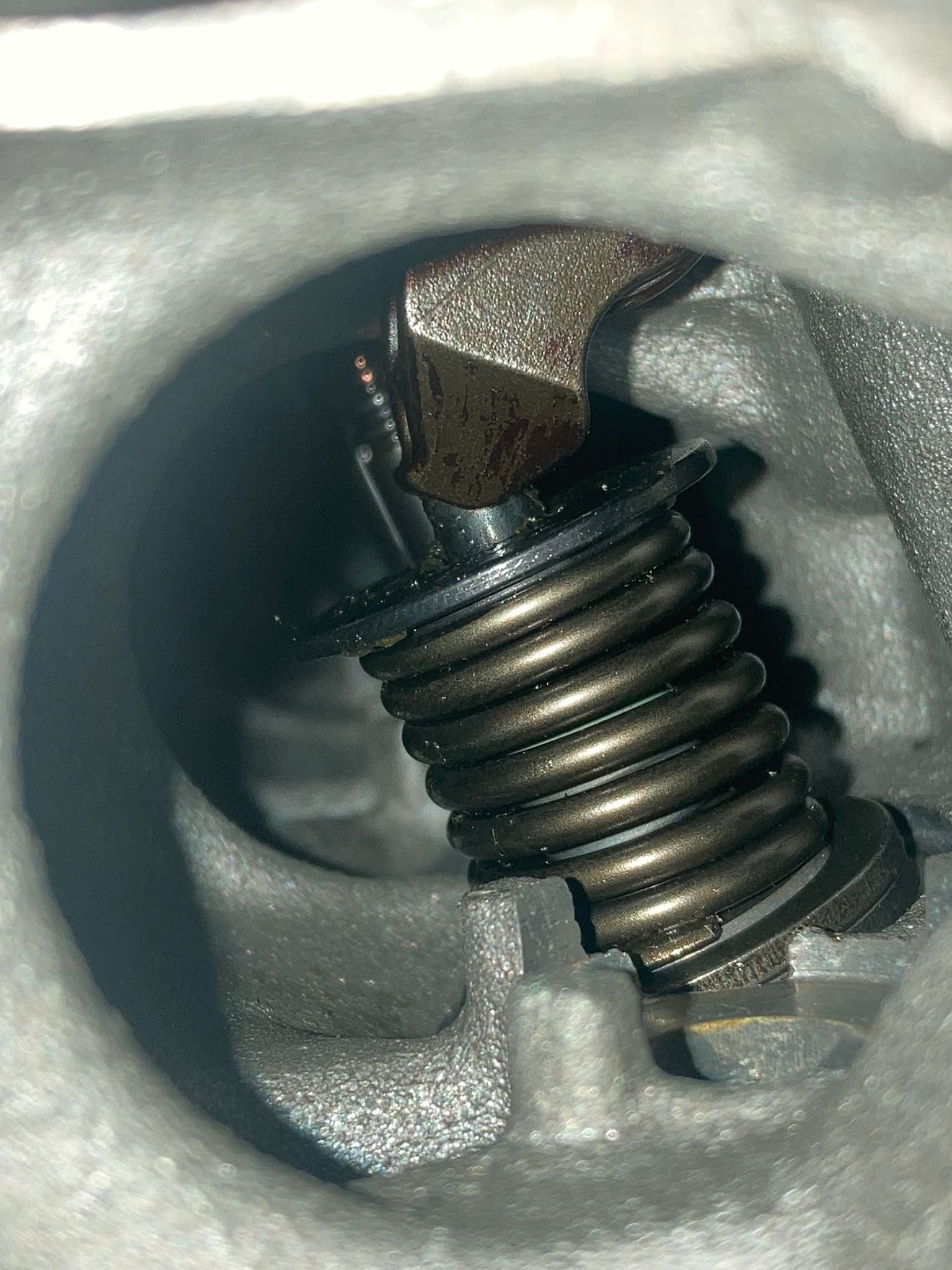

One particular issue that we've encountered is with engines that have performance camshafts with over 10.5mm of lift. We found that the valve stems tend to wear down, and the rocker arm can become dislodged, which can cause engine misfire and worst case scenario, a big engine failure due to the valve getting stuck open.

After we discovered this problem, we set off on a mission to find the root cause. We put all of our knowledge and resources into finding a solution, and we're happy to report that we've come up with an effective fix.

We have made some exciting findings during our recent engine testing. We have identified valve stem wear as a potential problem, which can occur when the rocker arm exceeds a certain angle causing an increase in pressure over the tip, leading to premature wear and eventually failure. This issue is more common in engines with non-OEM camshafts with higher lift and can be identified by an engine becoming tappety.

Another issue we discovered is the dislodgement of the rocker arm. This was evident during testing and enabled us to address the problem quickly, especially as we had experienced similar issues with other engines. The rocker arm can become loose and fall off its place due to harsh operating conditions and lower oil pressure, making it essential to ensure proper maintenance.

Although these findings may sound concerning, they provide valuable insight into improving engine performance and reliability. By identifying these issues, we can address them before they turn into more significant problems and continue to develop more advanced engines for our customers to enjoy.

Our solution has been put through the wringer for the past year and we are proud to announce that it has passed with flying colors. Our valves are built with two different metals and have been hardened to withstand even the harshest conditions. One of the key features is the longer stem which allows us the ability to run up to 13mm of lift without any issues

Many have asked about the wear and tear on the valve stem. We have conducted extensive testing and recommend running a max of 11mm lift on stock valves to prevent excessive wear and on our ones 13mm . As seen in the pictures, our valve stem area is much different and provides added protection when in use.

We are confident in our product and stand by its durability and performance. Don't just take our word for it, try it yourself. Our solution has been put through the ringer and has come out on top. Give it a test drive and see for yourself.

kit consist of 16 valves, nemonic material

available sizes

Inlet 33/34mm

ex 30.5/31.5mm

*these will require camshafts modification, we offer a choice of two great Profiles to go along with these valves

We've been hard at work developing engines for many years, and along the way we've encountered just about every problem you can imagine. But with each challenge, we've always found a way to overcome it. In fact, we've come up with solutions for issues that simply weren't available on the market.

One particular issue that we've encountered is with engines that have performance camshafts with over 10.5mm of lift. We found that the valve stems tend to wear down, and the rocker arm can become dislodged, which can cause engine misfire and worst case scenario, a big engine failure due to the valve getting stuck open.

After we discovered this problem, we set off on a mission to find the root cause. We put all of our knowledge and resources into finding a solution, and we're happy to report that we've come up with an effective fix.

We have made some exciting findings during our recent engine testing. We have identified valve stem wear as a potential problem, which can occur when the rocker arm exceeds a certain angle causing an increase in pressure over the tip, leading to premature wear and eventually failure. This issue is more common in engines with non-OEM camshafts with higher lift and can be identified by an engine becoming tappety.

Another issue we discovered is the dislodgement of the rocker arm. This was evident during testing and enabled us to address the problem quickly, especially as we had experienced similar issues with other engines. The rocker arm can become loose and fall off its place due to harsh operating conditions and lower oil pressure, making it essential to ensure proper maintenance.

Although these findings may sound concerning, they provide valuable insight into improving engine performance and reliability. By identifying these issues, we can address them before they turn into more significant problems and continue to develop more advanced engines for our customers to enjoy.

Our solution has been put through the wringer for the past year and we are proud to announce that it has passed with flying colors. Our valves are built with two different metals and have been hardened to withstand even the harshest conditions. One of the key features is the longer stem which allows us the ability to run up to 13mm of lift without any issues

Many have asked about the wear and tear on the valve stem. We have conducted extensive testing and recommend running a max of 11mm lift on stock valves to prevent excessive wear and on our ones 13mm . As seen in the pictures, our valve stem area is much different and provides added protection when in use.

We are confident in our product and stand by its durability and performance. Don't just take our word for it, try it yourself. Our solution has been put through the ringer and has come out on top. Give it a test drive and see for yourself.

kit consist of 16 valves, nemonic material

available sizes

Inlet 33/34mm

ex 30.5/31.5mm

*these will require camshafts modification, we offer a choice of two great Profiles to go along with these valves